Silicon carbide stands out in the world of high-performance ceramics as an unheralded hero, always standing its ground against extreme temperatures and chemical corrosion. Silicon carbide tubes play an integral part in critical industries such as aerospace, power generation, chemical processing and semiconductor manufacturing.

In this article, we’ll look into why silicon carbide tubes are such an invaluable asset and their uses in various environments.

Hardness

Silicon carbide is one of the hardest materials on Earth with a hardness equivalent to that of diamond, giving it incredible strength and durability. Furthermore, this extreme hardness enables resistance against degradation from various chemicals such as strong acids and alkalis; meaning it can withstand harsh environments as well as challenging industrial processes.

Mechanical stress resistance also makes the material popular with gas turbine engines, improving performance, efficiency and service life while its corrosion and wear resistance offer significant advantages in demanding industrial applications.

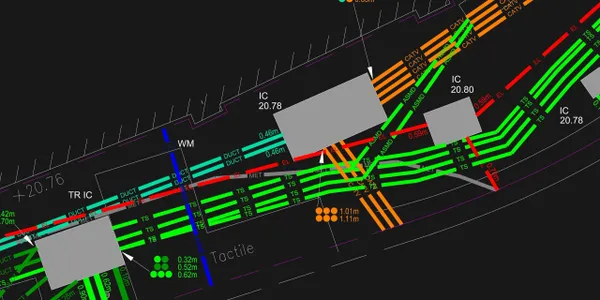

our silicon carbide tubes undergo intensive inspection and testing to meet industry standards. We manufacture our own tubes in an advanced facility and can customize dimensions and lengths according to your application needs. As part of our quality control inspection process, each tube undergoes hydrotesting at 165-186 bar pressure; so get in touch with us now and discover how our SiC tubes can benefit your business!

Corrosion Resistance

Silicon carbide stands up well against temperatures up to 2000degC and offers superior heat resistance compared to other materials, making it the material of choice for high-temperature applications in critical industries. Furthermore, silicon carbide conducts thermal energy 50% better than graphite and 10% better than most metals – helping end-users increase efficiency while decreasing operational costs.

These characteristics make aluminum an excellent material choice for various industrial applications, including metal smelting, chemical processing and aerospace engineering. Furthermore, it makes an ideal material choice for components used in oil drilling as it can withstand high temperatures while remaining corrosion resistant.

we manufacture sintered, reaction bonded and recrystallized silicon carbide tubes depending on their use. Each type has unique advantages but they all share high hardness, high use temperature resistance, good oxidation resistance and abrasion resistance properties. Their use includes ceramic kiln shelves, beams rollers cooling air pipes thermocouple protection tubes temperature measurement tubes burner nozzles wear-resistant components.

High Thermal Conductivity

Heat is of primary concern in any environment; therefore transferring it efficiently is also of utmost importance. Silicon carbide excels at conducting thermal energy by 50% over graphite and 10% better than most metals – guaranteeing uniform heat dissipation.

SSiC tubes offer exceptional resistance against degradation from various acids, alkalis, solvents and other chemicals used in power industry applications, making them perfect for this application. Furthermore, these resilient tubes can withstand mechanical stress while remaining resilient under high temperatures and abrasive environments – perfect for power industry use!

Silicon carbide ceramic components, unlike other ceramics, can withstand very high temperatures. This makes it an excellent choice as cladding material in nuclear reactors due to its low through-thickness temperature gradient that helps achieve higher fuel performance while simultaneously reducing internal stress on cladding material and internal stresses resulting from fuel performance increases – leading to higher efficiency, less maintenance cost and improved operational safety. Furthermore, silicon carbide’s thermal processing properties make it an excellent component choice for industrial furnaces or thermal processing units; additionally it is perfect as an SSiC is designed specifically to refuel nuclear refueling tubes as SSiC can withstand its rigorous environments and extreme temperatures that occur in this process.

Long Life

Silicon carbide stands up well to corrosion-laden environments, unlike many other materials which quickly degrade. As it resists degradation from various acids, silicon carbide makes an ideal material choice for applications involving metal smelting, chemical production and aerospace engineering.

Silicon carbide conducts thermal energy faster than graphite and exhibits excellent wear resistance, making it suitable for various applications like spray nozzles, ceramic tubing and cyclone lining.