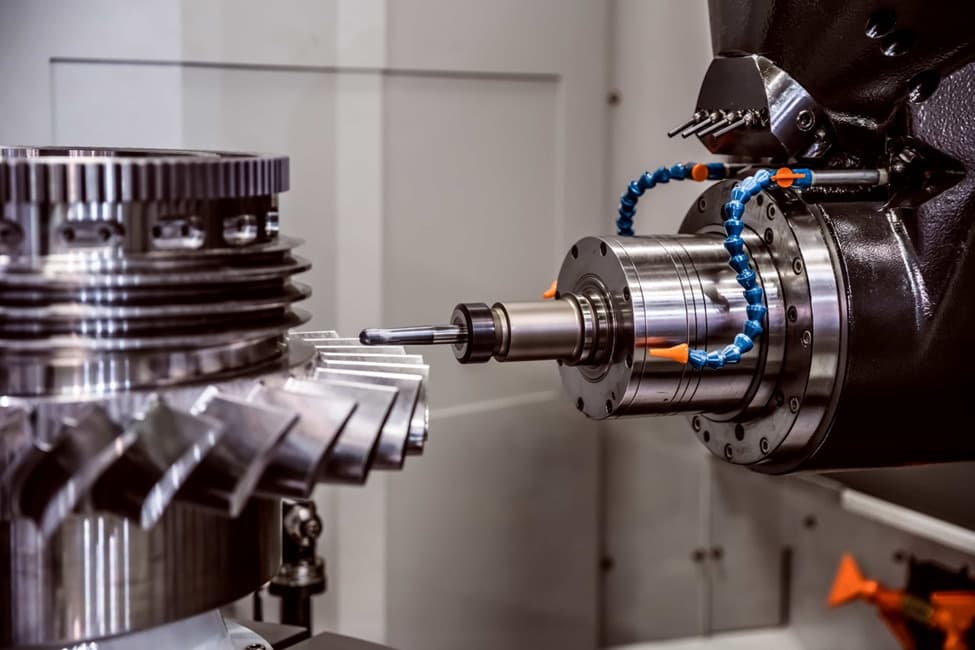

Investing in machine tools can significantly boost a company’s manufacturing capabilities and output. However, finding the right machine tool provider is crucial to ensuring you get equipment that meets your specific production needs. This article outlines key strategies for selecting machine tool factory and getting the most value from your investment.

Choosing the right machine tool provider in Saudi Arabia enables companies to enhance their machining capabilities. Machine tools encompass various power-driven equipment like lathes, presses, drills, etc. that shape, form, or finish metal or other materials. With the right machine tool factories and providers, businesses can increase efficiency, consistency, and precision in manufacturing. This article offers tips on selecting suitable machine tool providers in Saudi Arabia to obtain optimized solutions for your production requirements.

Assessing Your Production Requirements

The first step is clearly identifying your existing and future production needs. What materials do you work with? What processes, like milling, turning, or grinding, are required? The machine tools must be suitable for your specific materials and capable of delivering the necessary accuracy, precision, and surface finish. Evaluating current workflow and bottlenecks will determine what capabilities need improvement. This analysis informs the type of equipment and technical specifications required. Keeping long-term business goals in mind while investing in machine tools prevents capability gaps later.

Researching Providers’ Offerings and Expertise

With clear production requirements in hand, extensive research on potential machine tool providers in Saudi Arabia is vital. Examine the range of machine tools they offer across functions like cutting, forming, and additive manufacturing. Review case studies showcasing their experience and expertise in your industry. For example, if you manufacture automotive parts, seek out providers experienced in supplying that sector. Ask how they stay updated on the latest innovations and technologies in the machine tools domain. Choose a knowledgeable partner that comprehensively understands modern manufacturing needs and equipment.

Evaluating Technology, Productivity, and Precision

Closely compare machine tool models from different providers based on key aspects that impact productivity, precision, and costs.

- Technology used: Advanced technologies like motors, drives, control systems, automation, and sensors ultimately determine the machine’s capabilities. Assess those critical components powering the equipment.

- Accuracy and precision: examine equipment tolerances and the ability to consistently produce parts within tight dimensions. Validate certifications for quality assurance.

- Production volumes: Calculate expected cycle times and match them to your volume requirements. Evaluate the secondary processes involved to estimate the overall throughput.

- Ease of operation: intuitive controls, programming software, and interfaces enable simpler machine operation, requiring less manual intervention.

- Operating costs: In addition to capital expenditure, operating expenses like energy consumption, maintenance needs, and consumables play a role.

Selecting equipment that optimizes these factors ensures maximum productivity from your machine tool investment.

Validation Testing and Trials

If possible, request a demo test run on potential machine tools using sample materials during the provider evaluation process. Observe the machining process closely, checking aspects like programming, setup time, tool changes, maintenance access, and ease of operation. Validate actual performance metrics like tolerance capabilities, accuracy, surface finish, and cycle times during your trial. Hands-on testing showcases how the equipment performs for your specific application. If trials are not feasible, ask for sample parts to be machined and strict validation reports. Thorough testing ensures the machine tools deliver consistent quality output and the desired productivity gains.

Training and post-purchase support

Factor in the provider’s training, installation, commissioning, and ongoing post-purchase support. Comprehensive operator and programmer training ensures correct machine use. Installation supervision by experts checks proper setup for smooth production startup. Robust technical assistance for maintenance, spare parts supply, and modernization upgrades during equipment lifetimes avoids unnecessary downtime. Carefully weigh these facets while opting for a machine tool provider for maximum value.

Choosing local providers

Seeking machine tool providers located nearby or within Saudi Arabia offers multiple advantages. Immediate technical service and support enable faster issue resolution. Local development and customization as per your evolving requirements are easier through close supplier partnerships. Geographic proximity also ensures timely delivery of spare parts and lowers logistics costs. Additionally, communication and responsiveness improve with accessible suppliers speaking your language, facilitating better collaboration.

Leverage data and analytics.

Advanced machine tools nowadays offer extensive data and analytics capabilities. Collecting real-time production data on factors like equipment effectiveness, utilization rates, cycle times, and quality metrics enables informed decision-making. Ask providers about built-in IoT sensors, controllers that collate statistics, and monitoring software to leverage analytics. Analytics-driven optimization and preventive maintenance dramatically improve overall equipment effectiveness.

Upgrade Paths

Alternatively, renting possibilities for the machine tools should also be taken into account. This provides the option to change the models or introduce other tools as production continues. Renting fast-tracks the acquisition process, allowing for a quicker response to market demands. Ensure that the timeframes, costs, transportation needs, and damage liabilities are clearly stated in the rental contracts. Review the renewal requirements and termination agreements before entering into the contracts. Rentals create a situation where machine tool upgrades take place in an effortless manner based on strategic priorities, as they provide operational and financial flexibility.

Focus on energy efficiency

Due to the increased energy prices worldwide, the cost of operation is influenced by the machine tools’ energy consumption. First, review the constructed designs, controllers, and all operations in order to identify any opportunities for saving energy. Providers are coming out with many innovations in domains such as energy-efficient motors, actuators, power management systems, and compressed air systems to minimize the carbon footprint. Energy-saving choices like the helical rack and pinion simplify the power transmission. Shut-off controls during idle times reduce waste. Baffled toolholders reduce air leakage. While evaluating the machine tools, consider their long-term energy savings potential. As sustainability becomes more critical, energy-efficient equipment saves a significant amount of money and also provides environmental benefits.

Conclusion

Identification and investment in the appropriate machine tools providers in saudi arabia can be seen to have a significant role to play in the productivity levels of manufacturing. Companies can achieve the best possible gains from this investment if they apply an analytical approach involving current and future needs and in-depth provider evaluation. Looking at such factors as accuracy, technological compatibility, running costs, and post-sale assistance while choosing the suppliers also guarantees the best value. Customized responsiveness is required for optimized manufacturing systems, which comes with partnering with knowledgeable local providers. The way is paved for the true transformative benefits of such advanced machines through a systematic machine tool procurement strategy aimed at long-run production improvement.