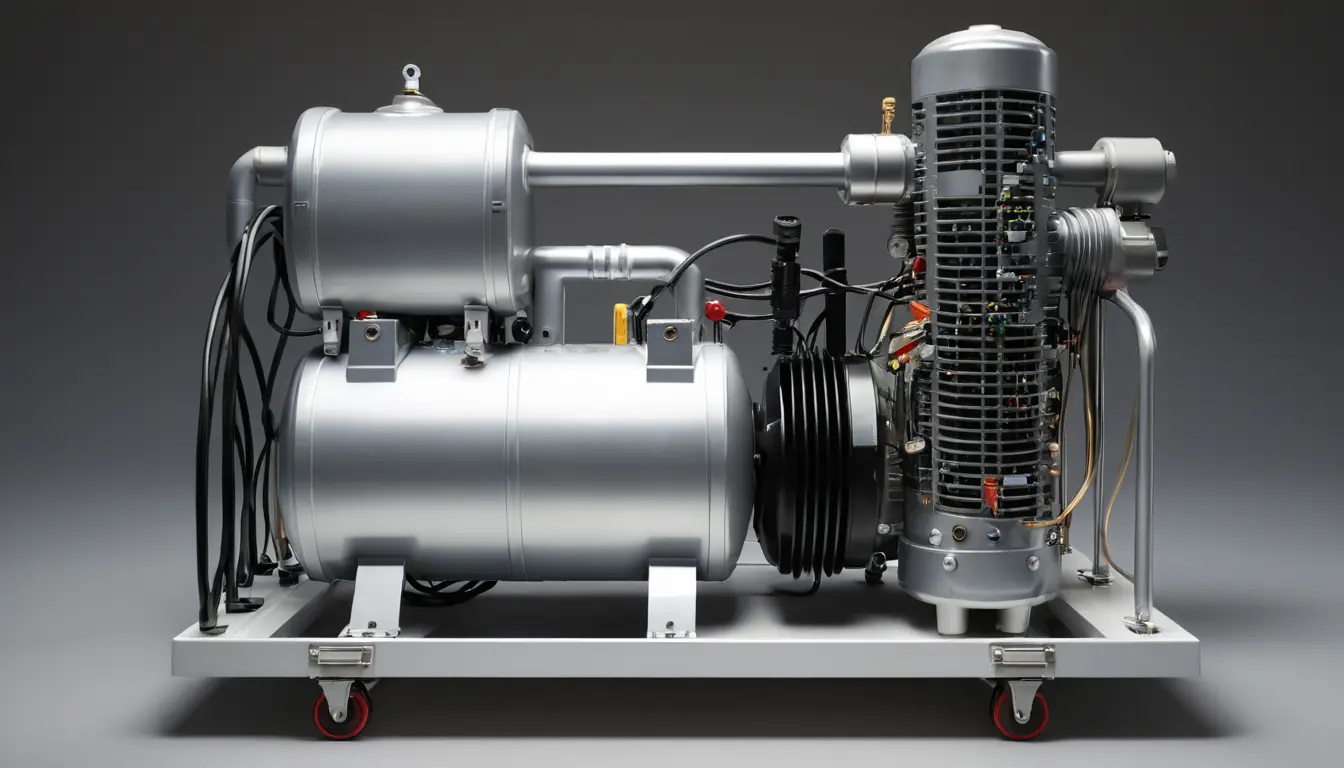

Air compressors are versatile tools that serve various purposes, from powering industrial machinery to inflating tires at home. However, like any machine, an air compressor requires regular maintenance to ensure optimal performance and longevity. By following the right maintenance practices, you can protect your investment and avoid costly repairs.

Hyundai Power: A Trusted Name in Tools and Equipment

When it comes to reliable industrial tools, Hyundai Power is a name that stands out. Offering a comprehensive range of Hyundai-branded products, the company caters to various needs, including power generators, home appliances, solar solutions, lighting, gardening tools, and industrial equipment. Their commitment to quality and innovation makes Hyundai Power a go-to brand for professionals and homeowners alike.

Read Your Air Compressor Manual

Every air compressor model is unique, and understanding its specific requirements is crucial for proper maintenance. Start by thoroughly reading the user manual provided by the manufacturer. The manual contains essential information about operating procedures, maintenance schedules, and troubleshooting tips tailored to your compressor.

Regularly Check and Replace the Air Filter

The air filter is a vital component that prevents dirt and debris from entering the compressor. Over time, the filter can become clogged, reducing the efficiency of the machine. Inspect the filter regularly and replace it if it appears dirty or worn out. A clean air filter not only improves performance but also extends the lifespan of your compressor.

Drain Moisture from the Tank

Moisture buildup is a common issue in air compressors due to condensation inside the tank. Allowing moisture to accumulate can lead to rust and corrosion, which damages the tank. Make it a habit to drain the tank after every use by opening the drain valve located at the bottom. This simple step can significantly enhance your compressor’s durability.

Inspect for Leaks

Air leaks can reduce the efficiency of your compressor and increase energy costs. Periodically check all hoses, fittings, and connections for any signs of leaks. If you notice any hissing sounds or reduced pressure, address the issue promptly by tightening connections or replacing damaged parts.

Change the Compressor Oil

For oil-lubricated air compressors, changing the oil is essential to ensure smooth operation. Old or dirty oil can cause the compressor to overheat and lead to premature wear. Follow the manufacturer’s recommendations for the type of oil to use and the frequency of oil changes. Typically, this is done every three months or after a specific number of operating hours.

Clean and Tighten Components

Dust, dirt, and vibrations can loosen components over time. Regularly clean the compressor’s exterior to remove debris and inspect all bolts and screws for tightness. Ensuring all parts are secure can prevent malfunctions and keep the machine running smoothly.

Replace Worn Belts

If your air compressor uses belts to operate, check them periodically for signs of wear or damage. Worn belts can cause inefficient performance and unexpected breakdowns. Replace any cracked or frayed belts immediately to avoid disruptions in your workflow.

Check the Safety Valve

The safety valve is a critical component that prevents the tank from overpressurizing, ensuring safe operation. Test the safety valve by pulling the ring to release air. If it doesn’t function correctly, have it inspected or replaced by a professional to ensure the safety of the equipment.

Keep the Compressor in a Clean Environment

The environment in which you store your air compressor plays a significant role in its maintenance. Keep the compressor in a clean, dry, and well-ventilated area to minimize exposure to dust, moisture, and extreme temperatures. Proper storage can protect the machine from unnecessary wear and tear.

Schedule Professional Maintenance

While regular checks and maintenance can address many issues, scheduling a professional inspection annually is highly recommended. A professional technician can identify potential problems early and ensure that your compressor operates at peak efficiency.

Benefits of Proper Air Compressor Maintenance

Maintaining your air compressor provides several benefits. It ensures consistent performance, reduces the risk of breakdowns, and extends the lifespan of the machine. Additionally, a well-maintained compressor operates more efficiently, saving you money on energy costs and repairs in the long run.

Conclusion

Regular maintenance is the key to getting the most out of your air compressor. By following the steps outlined above, you can keep your compressor running efficiently and enjoy long-lasting performance. Whether you use your air compressor for professional or personal purposes, proper care will protect your investment and ensure it remains a reliable tool for years to come.