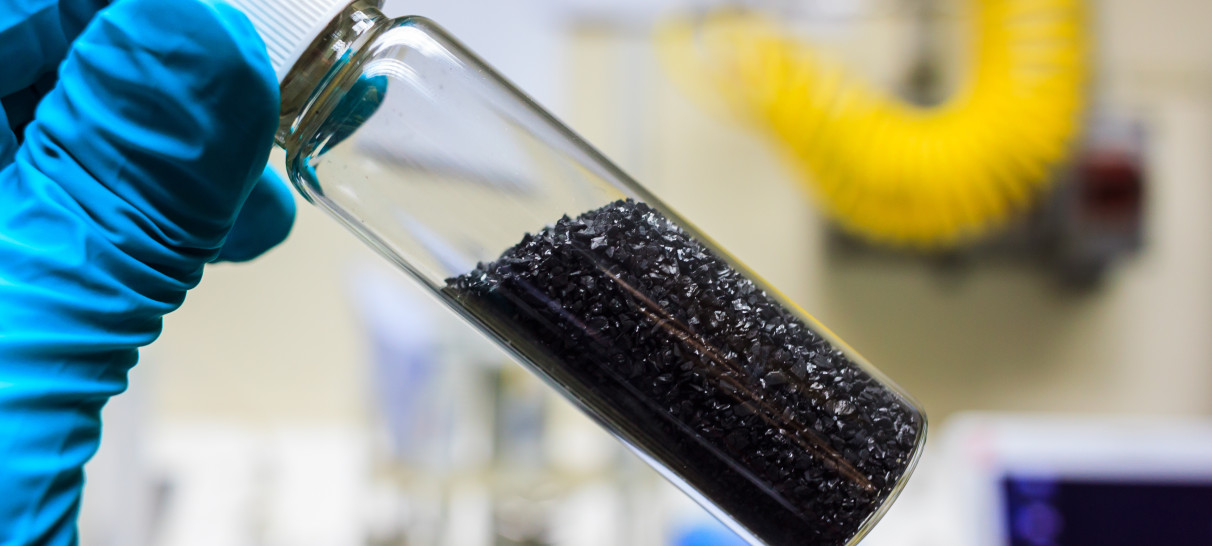

In very simple terms, carbon black used in rubber is the unsung hero of the modern-day industrial world because this is the only thing that has been successful in bringing a good number of innovations in today’s first-speed world of technical advancements. carbon black used in rubber is one such hero that has frequently been concealed from view and is basically a very overlooked wonder of material science. It comes with a significant impact on the number of businesses and also provides people with a significant number of benefits.

Some of the best possible benefits that you need to know about carbon black used in rubber have been very well explained as follows:

- Improving the overall durability: The concept of carbon black used in rubber will be definitely successful in terms of improving the overall durability of any process and further will be able to provide people with a supreme level of strength in the rubber compounds. In turn, it will be helpful in increasing the resilience of the tires to road hazards and will be able to ensure that the interlocking of the microscopic carbon black particles will be very well sorted out. This will not only be helpful in improving the lifespan of the tires but also make sure that things will be very well done in the right direction without any issues. Eventually, it also helps in contributing to the overall improvement of safety with compliance with environmental responsibility without any problem.

- Providing people with very high tensile strength: The reinforcement associated with carbon black used in rubber makes it very well dispersed throughout the rubber metrics on the microscopic level. This will be very well successful in providing the carbon particles with the best opportunity to enjoy synergy and work with other polymers without any problem. In addition to the basics of durability, reinforcement associated with that very well provides people with a good number of benefits and also helps in maintaining the overall ability to resist without being stretched at any point. The testing in this particular case has been very successful in providing people with thin-size strength ratings and also makes sure that a standardized support system will be very well present throughout the process. It will provide people with the best possible smaller cross-section profiles and also help in making sure that material costs will be definitely under control. The bottom line in this particular case is that everyone will be able to deal with the basic elements of components without any problem and further will be able to stand tremendous strength without any problem at any point in time. So, this scenario of breakage in the mechanical rubber products will be very well eliminated in this case and chances of failure will be bare minimum.

- Helpful in improving the thermal conductivity: Pure rubber is basically an effective electrical and thermal insulator which is sometimes problematic in basic applications where the dissipation of heat is important. So, using carbon black in rubber in this particular case is important because it will address the issues by providing people with a very high level of thermal and electrical conductivity throughout the rubber material. This will also be helpful in providing the rubber carbon compounds with the best possible dissipation of heat that will be effectively dealt with without problems in the whole process. This will be eventually successful in terms of protecting the equipment from malfunctioning and prolonged use and also making sure that it can be easily used for a very high level of reliability in the applications. Involving the electrical contacts in this case and handling the delicate semiconductor systems becomes very easy which makes it extremely suitable for multiple purposes without any problem. The improved thermal and electrical conductivity provided by the carbon black used in rubber provides the designers with the best level of support and also makes sure that heat management, as well as electric electrical applications of rubber, will be very well facilitated without any issue.

- Providing people with the best possible chemical resistance: Chemical resistance in addition to the physical very well helps provide people with a significant number of benefits and also makes sure that there will be no chance of any kind of degradation with time. Carbon particles will be very tightly bonded within the rubber metrics which ultimately helps in providing people with the best possible barrier effect and makes the fluid penetration very much difficult. In this case, the exposure to the growth of substances will be the bare minimum and everyone will be able to deal with the basic products without any problem. Reliability In this case very well helped in demanding durability and also helped in promoting the overall longevity without any problem in the whole process. This will be very well successful in terms of providing people with a supreme level of chemical resistance and also help in making sure that overall goals will be very proficiently achieved.

- Helpful in reducing the coefficient of friction: When the coefficient of friction is low, carbon black used in rubber will definitely provide people with the best level of support and further will be able to ensure that the overall element of drag and resistance will be the bare minimum throughout the process. The dramatic reduction of friction in this particular case makes the carbon black used in rubber very well suitable for high-wear applications and also helps in supporting the suspension with engine mount and other associated things. Eventually, this will be helpful in maximizing the overall performance and also make sure that life span support will be there without any problem. This will be definitely helpful in providing people with a very high-level of energy efficiency and also make sure that motion will be very smooth without any practical difficulty at any point in time. Whenever the carbon filter is very well lubricated, there will be no chance of any kind of undesirable issues, and further, things will be very easily sorted out in terms of safety-critical applications.

In addition to the above-mentioned points, shifting the focus to the use of carbon black from waste tires is definitely very important for modern companies so that everyone can have access to high-performance material across many industries now as well as in the future to enjoy growth.