In today’s fast-paced manufacturing environment, downtime is the enemy. Every minute that a production line stands still can translate into significant financial loss. Imagine a vast orchestra where every instrument must play in harmony. If one note goes offbeat, the melody falters. Predictive maintenance (PdM) is like the conductor of this orchestra — listening carefully to every instrument (or machine), identifying early signs of disharmony, and intervening before a breakdown occurs.

By using IoT sensor data, predictive maintenance transforms reactive maintenance into a proactive strategy that ensures operational excellence and cost efficiency.

The Shift from Reactive to Predictive

Traditional maintenance operates much like firefighting — fixing problems only after they occur. In contrast, predictive maintenance anticipates the fire before the first spark. Sensors embedded in equipment continuously monitor variables such as temperature, vibration, and pressure.

When analysed through advanced analytics models, these data points reveal patterns that signal early signs of wear and tear. This proactive insight allows maintenance teams to schedule interventions precisely when needed, reducing both unexpected failures and unnecessary maintenance costs.

Professionals pursuing a business analyst certification course in Chennai often study such real-world use cases, learning how data-driven insights can optimise operations and drive measurable business results.

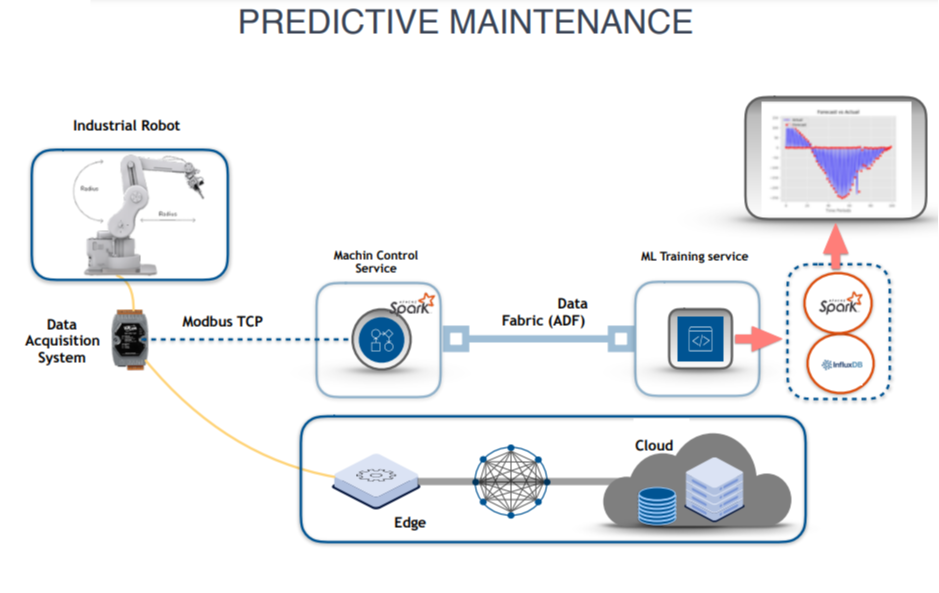

How IoT Sensors Drive Predictive Insights

Think of IoT sensors as the “ears” and “eyes” of modern machinery. They constantly capture real-time performance data, transmitting it to central systems for analysis. Machine learning models then compare current sensor readings to historical data, identifying even subtle deviations from normal operation.

For example, an increase in vibration in a motor might indicate an impending bearing failure. By catching this anomaly early, engineers can replace parts before a major breakdown disrupts production.

Over time, this approach not only reduces repair costs but also extends equipment life, making predictive maintenance a cornerstone of smart manufacturing systems.

The Analytical Backbone of Predictive Maintenance

Behind the scenes, predictive maintenance relies on a combination of statistical modelling, machine learning, and domain expertise. Analysts clean, integrate, and process massive datasets from sensors to identify patterns of degradation.

Techniques like regression models, neural networks, and decision trees help predict when a machine will fail based on its historical behaviour. Moreover, visualisation tools enable teams to interpret these insights intuitively through dashboards and alert systems.

In structured learning settings such as a business analyst certification course in Chennai, students explore how to apply these analytical methods to transform raw sensor data into actionable business intelligence.

Business Impact: Saving Time, Cost, and Reputation

The ripple effects of predictive maintenance are profound. Manufacturers adopting PdM strategies report reduced downtime, lower operational costs, and improved worker safety. More importantly, they gain a reputation for reliability, which strengthens client trust.

Companies can also use the collected data for broader business decisions — optimising inventory for spare parts, improving supply chain forecasts, and enhancing product quality based on machine performance insights.

Predictive maintenance thus moves beyond the factory floor, influencing financial forecasting, logistics, and customer satisfaction — making it not just a technical upgrade, but a strategic one.

Overcoming Challenges in Implementation

Despite its benefits, predictive maintenance isn’t without hurdles. Integrating legacy systems, handling vast amounts of sensor data, and ensuring data accuracy are significant challenges. Organisations also need skilled professionals capable of interpreting analytical outputs effectively.

Furthermore, cybersecurity risks emerge when connecting industrial systems to the internet, making robust security protocols essential. Successful implementation requires not just technology, but a cultural shift toward data-driven thinking.

Conclusion

Predictive maintenance exemplifies the perfect blend of technology and foresight — turning data into decisions and machines into self-aware systems. By capturing and analysing sensor data, manufacturers can transform potential disruptions into opportunities for optimisation.

As industries transition to smarter operations, professionals with analytical and problem-solving skills will spearhead this transformation. Courses empower individuals to comprehend these complex systems, preparing them to drive innovation and reliability in the modern manufacturing landscape.

Predictive maintenance, ultimately, is not about fixing machines — it’s about mastering foresight. It’s where analytics, technology, and human intelligence converge to ensure that every note in the industrial symphony plays in perfect harmony.