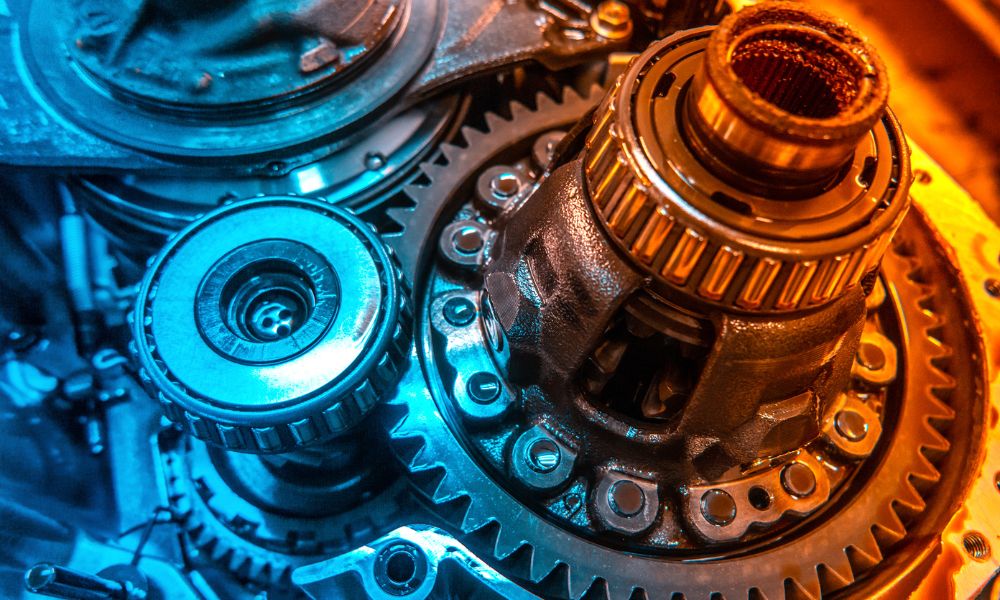

Workshop repair manuals, often referred to as service manuals or repair guides, are indispensable tools for individuals involved in the maintenance, repair, or servicing of machinery, vehicles, or equipment. These manuals serve as comprehensive references, providing step-by-step instructions, diagrams, and essential information to ensure that tasks are carried out accurately and efficiently. Whether you’re a professional technician, a car enthusiast, or a do-it-yourselfer, workshop repair manuals are crucial resources that simplify complex repair procedures Workshop Repair Manual.

What Are Workshop Repair Manuals?

Workshop repair manuals are comprehensive documents that contain a wealth of information pertaining to a specific machine, vehicle, or equipment. They are typically created by the manufacturers or third-party publishers with access to manufacturer specifications. These manuals encompass a wide range of topics and procedures, including:

- Maintenance: Detailed schedules for routine maintenance, including tasks like oil changes, filter replacements, and inspections.

- Repairs: In-depth procedures for diagnosing and rectifying issues, featuring step-by-step instructions and troubleshooting guides.

- Disassembly and Assembly: Instructions for disassembling and reassembling various components or systems, making it easier to access and repair specific parts.

- Wiring Diagrams: Schematics that illustrate the electrical connections and wiring of the machine, assisting with electrical repairs and installations.

- Torque Specifications: Precise torque values for bolts and fasteners, ensuring that components are properly secured.

- Technical Specifications: Comprehensive technical data, including engine specifications, dimensions, and capacities.

- Safety Procedures: Guidelines to guarantee the safety of technicians and users while performing repair and maintenance tasks.

Who Benefits from Workshop Repair Manuals?

Workshop repair manuals cater to a diverse range of users, including:

1. Professional Technicians:

Technicians working in repair shops, dealerships, and service centers rely heavily on workshop repair manuals to diagnose and repair vehicles and equipment accurately and efficiently.

2. Automotive Enthusiasts:

Car and motorcycle enthusiasts who enjoy working on their vehicles as a hobby utilize workshop repair manuals to complete various tasks, from routine maintenance to complex engine overhauls.

3. Equipment Operators:

Operators of heavy machinery and equipment, such as construction equipment or agricultural machinery, turn to workshop repair manuals to conduct maintenance and basic repairs, reducing downtime and repair costs.

4. Do-It-Yourself (DIY) Enthusiasts:

DIY enthusiasts who prefer to tackle home improvement projects or repair tasks on their own find workshop repair manuals to be invaluable resources, offering clear and precise instructions to ensure the work is done correctly.

The Advantages of Workshop Repair Manuals

The use of workshop repair manuals offers several advantages:

1. Accurate Repairs:

Workshop repair manuals provide precise, manufacturer-approved procedures, resulting in accurate repairs and a reduced risk of causing further damage.

2. Time and Cost Savings:

Efficiency is a key benefit. Workshop repair manuals help expedite diagnosis and repair, saving both time and money.

3. Safety:

These manuals often include safety guidelines that protect technicians and users during repair and maintenance tasks, ensuring a safer working environment.

4. Technical Information:

Access to detailed technical specifications and diagrams simplifies the understanding and repair of complex machinery or vehicles.

5. Extended Equipment Lifespan:

Regular maintenance and proper repairs extend the lifespan of machinery, vehicles, and equipment, ultimately reducing replacement costs.

Types of Workshop Repair Manuals

Workshop repair manuals are available in various formats:

1. Printed Manuals:

Traditional printed manuals remain widely used and are accessible for a wide range of vehicles and machines. They are often preferred for their portability and ease of use in a workshop.

2. Digital Manuals:

The advent of digital technology has led to the availability of digital workshop repair manuals, which can be in the form of PDF files or interactive digital guides. Digital manuals are easy to search, accessible on various devices, and may include multimedia elements such as videos or animations.

3. Online Subscriptions:

Some manufacturers and publishers offer online access to workshop repair manuals through subscription services. Subscribers gain access to an extensive library of manuals for a variety of equipment and vehicles.

Conclusion

Workshop repair manuals are indispensable resources for individuals engaged in maintenance, repairs, or servicing tasks. They offer detailed instructions, technical specifications, and safety guidelines to ensure that jobs are completed accurately and efficiently. Whether you’re a professional technician, an automotive enthusiast, or a DIY hobbyist, workshop repair manuals simplify complex tasks and help extend the lifespan of machinery, vehicles, and equipment, ultimately saving time and money in the long run.