Buy Pinterest Accounts With Followers

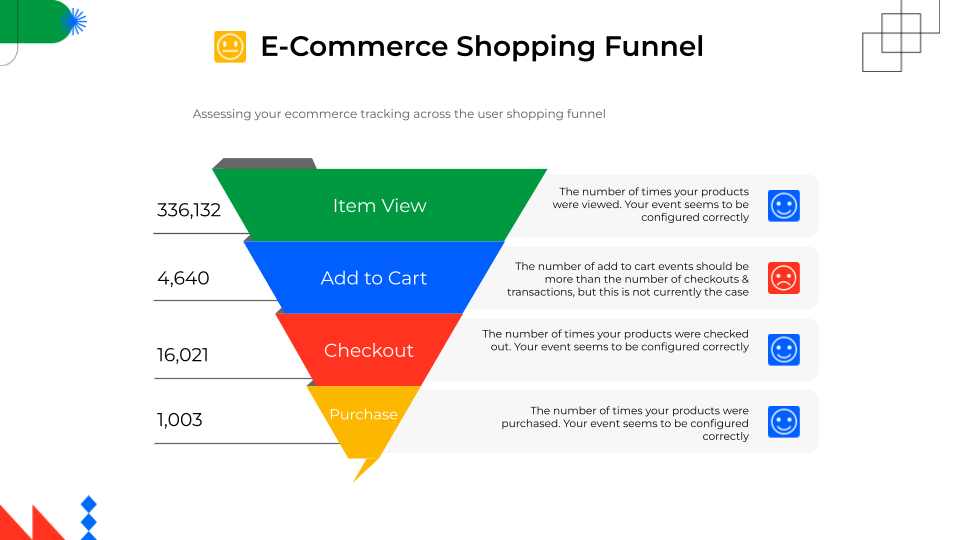

In the ever-evolving landscape of social media marketing, businesses are constantly seeking innovative ways to boost their online presence and connect with their target audience. One platform that has been gaining significant traction in recent years is Pinterest. With its visually appealing interface and highly engaged user base, Pinterest offers businesses a unique opportunity to…