This is what we mean by Sustainable Architecture! Low-E coating glass technology is one such technological innovation that helps to solve the two of the concerns mentioned above. This invention, which enhances thermal insulation, also aligns with sustainable building practices.

This solution is low-E coating glass technology, which enables a smooth, soft surface and utilizes different materials to reflect the heat while allowing natural sunlight through, which improves energy efficiency, thermal insulation, and indoor comfort. This reduces its energy consumption, UV exposure and building envelope efficiency. Low-E glass, available in both passive and solar control coatings, is common in residential, commercial and passive house designs. With choices including double and triple-glazed windows and smart glass applications, this technology promotes green building materials and sustainable architecture, making it an important consideration in modern energy-efficient structures.

An Overview of Low- E Coating Glass Technology

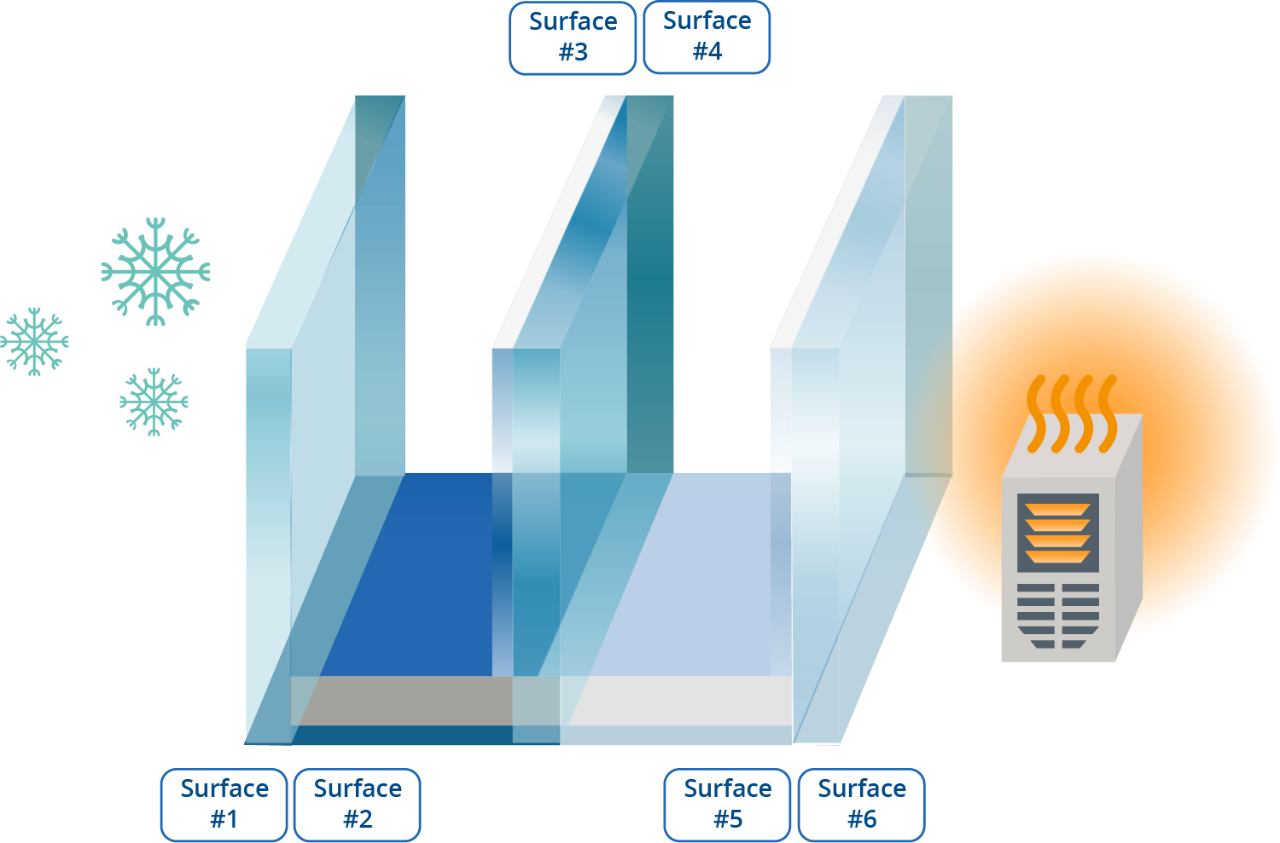

Low-emissivity (Low-E) glass has a microscopic, transparent coating that reflects infrared energy (heat) yet lets visible light pass through. This coating reduces the quantity of ultraviolet (UV) and infrared light that can be transmitted into a building, decreasing heat gain in summer and heat loss in winter. The result is a more stable indoor environment and less dependence on heating and cooling systems.

Types of Low-E Coatings

Low-E coatings are generally of two types:

Passive low emissivity (Low-E) coatings: These are specially made to ensure the maximum heat from solar radiation is captured, making them more suited for cooler climates where the extra warmth would be beneficial. They help capture natural heat and drive down the need for artificial heating.

Solar Control Low-E Coatings: Limit the solar heat entering a building, making them well suited for warmer climates. To this end, they reflect a significant amount of solar radiation, which keeps the interior cool.

Manufacturing Processes

There are two main ways to apply Low-E coatings to glass:

Pyrolytic (Hard Coat): The coating is applied in the manufacturing process of float glass where it bonds with hot glass surface to create a hard and durable coating. They are known to create solid coatings to extinguish many weather conditions.

Magnetron Sputter Vacuum deposition or Soft Coat: The MSVD (Magnetron Sputter Vacuum deposition or Soft Coat) is an off-line application performed in a vacuum chamber at room temperature which provides accurate control of layer properties in high-performance glazing solutions.

Benefits of Low-E Glass

Greater Energy Savings: Low-E glass minimizes the burden on HVAC systems by reflecting heat back to its source, helping to lower energy usage and utility bills.

Enhanced Thermal Insulation: The thermal insulation properties of Low-E glass assist in preserving continual indoor temperatures, which leads to tenant comfort.

UV Ray Protection: Low-E coatings help block harmful UV rays, which can fade or degrade interior furnishings over time.

Flexible in Terms of Glazing OptionsLow-E glass can be manufactured in double-glazed or triple-glazed options, making it adaptable to different performance needs like insulation or soundproofing capabilities.

Use in Modern Architecture

Low-E glazing or glass is a pillar of high-performance glazing in modern day building design. Its unique ability to balance light transmission with thermal control is ideal for multiple applications:

Convenience & Cost Savings: Homeowners enjoy lower energy bills and more comfort.

Business Buildings: Solve your building envelope energy issues to help meet sustainability goals and enhance the productivity of the people inside.

Passive House: Low-E glass is a key component in Passive House glazing, conforming with strict energy and indoor climate requirements.

New in Low-E Technology: A20895-228-TS.

Now, recent developments have seen the introduction of smart glass coatings that react to their changing environment. These coatings are able to adjust their characteristic dynamically, increasing light and heat transmission as needed to provide a building with increased energy efficiency.

Environmental Impact

Using Low-E glass goes along the path of green building materials, embodying sustainable living. Buildings with Low-E glazing consume less energy, leading to lower greenhouse gas emissions and supporting global climate change mitigation efforts.

Key Performance Metrics

The SHGC (Solar Heat Gain Coefficient) is the amount of solar radiation that passes through the glass, and is another important aspect to consider when choosing Low-E glass. A lower SHGC means better control of solar heat, which is especially advantageous in warm climates.

Conclusion

Low-E e-coated glass technology is a revolutionary force in building architecture that is useful for more than just energy efficiency and occupant comfort. One of the reasons for its popularity among architects and builders trying to create sustainable and comfortable environments is because of its versatility and performance.